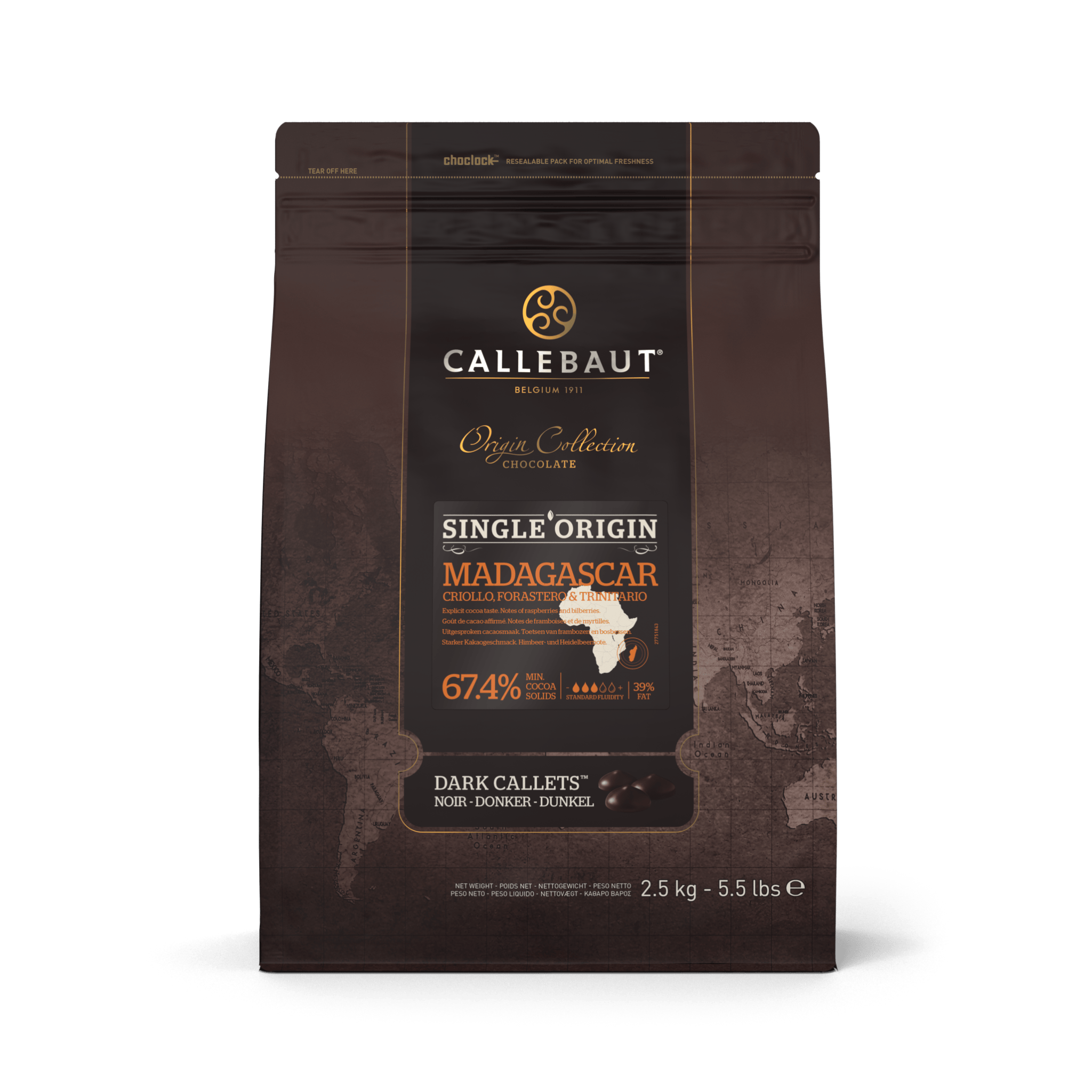

CALLEBAUT

MASTERS OF TASTE

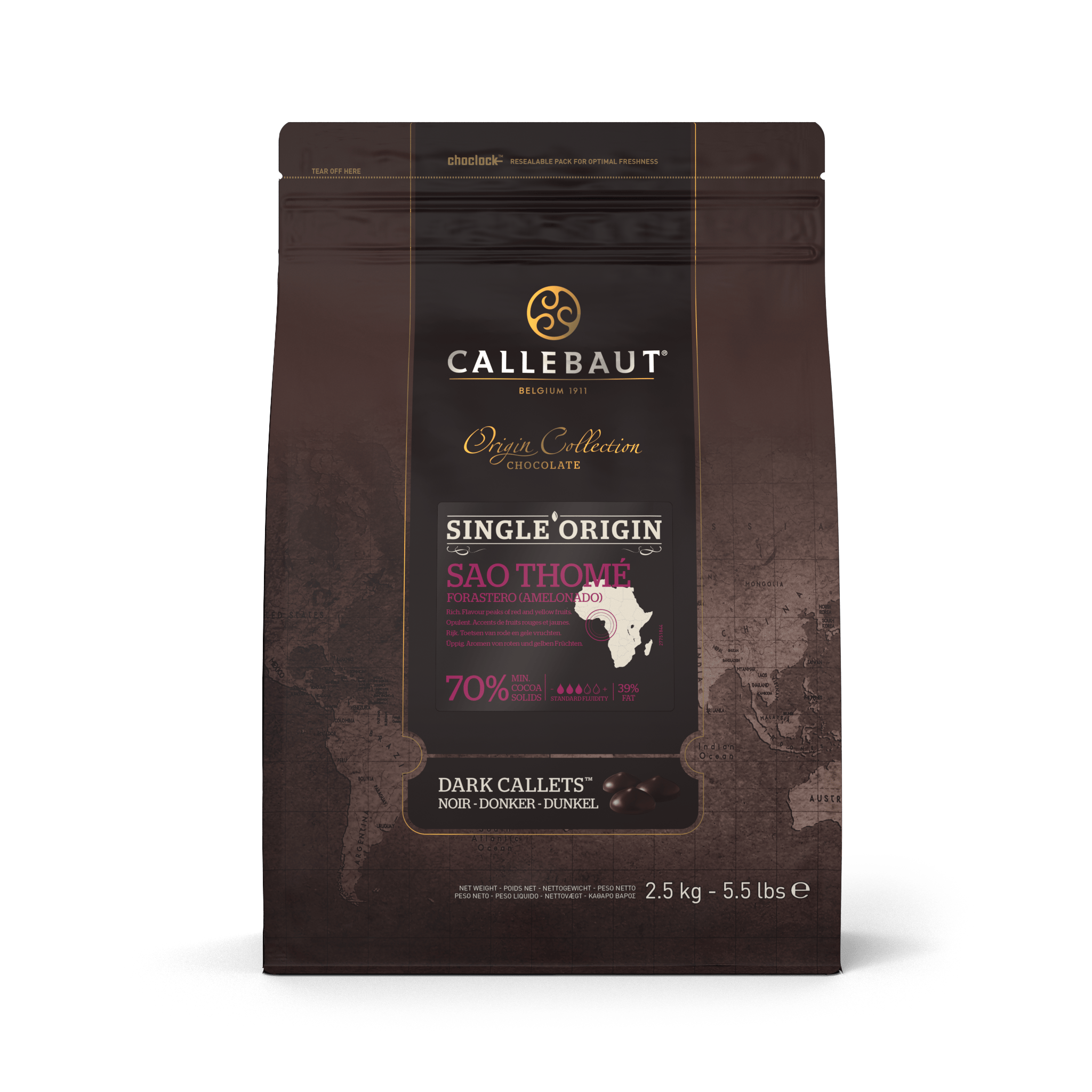

Every chef is unique. Every business is unique. And every day brings new challenges. But whatever they are, we’re here to take them on with you. With chocolate ingredients that help you win customers’ hearts. And help you in getting the job done. No matter what. This has been our goal for the last 100 years: creating the Finest Belgian Chocolate that chefs prefer. To craft at your best, every single day.

SINCE 1911

Already since then, our most iconic chocolates have become unmissable allies of chefs around the world. For their original taste. For the end results chefs achieve with them every day. And for taking sustainability at heart. For over a century, we’ve been crafting our chocolate from bean to bar in Belgium.

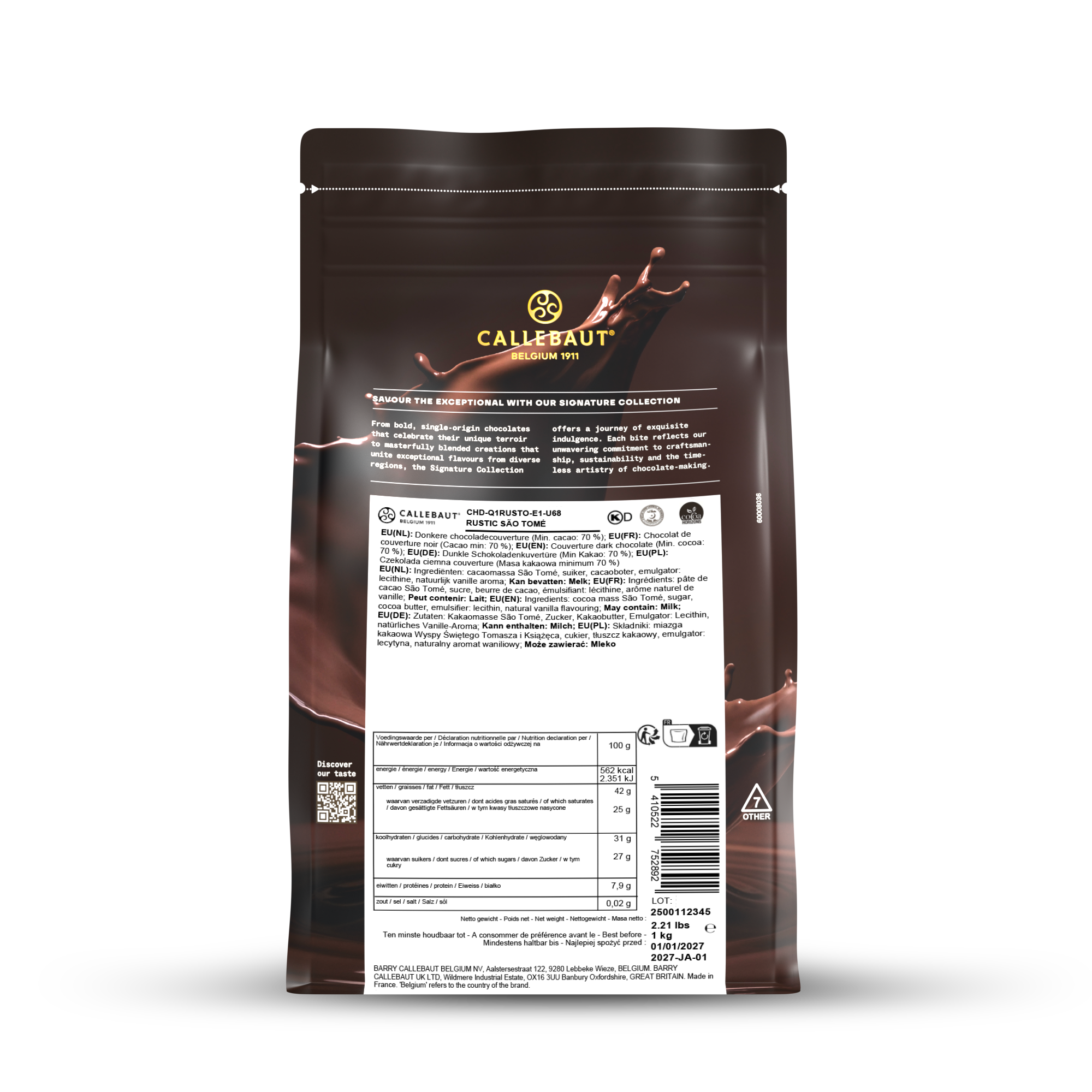

The Barry Callebaut Group, headquartered in Zurich, Switzerland, resulted from a merger in 1996 between two iconic chocolate makers, the Belgian Callebaut and the French Cacao Barry. During the past quarter of a century, Barry Callebaut Group became the world's leading manufacturer of high-quality chocolate and cocoa products, mastering every step in the value chain from the sourcing of raw materials to the production of the finest chocolates.